Anti-Scratch Sapphire Tube KY Method Oxide Polished

Product Details:

| Place of Origin: | China |

| Brand Name: | ZMSH |

Payment & Shipping Terms:

| Minimum Order Quantity: | 2 |

|---|---|

| Price: | 10 USD |

| Payment Terms: | T/T |

|

Detail Information |

|||

| Material: | Sapphire | Hardness:: | 9.0 |

|---|---|---|---|

| Length:: | 1-1500mm | Anti-scratch:: | High |

| Highlight: | Oxide Polished Sapphire Tube,KY method Oxide Polished Sapphire Tube,KY method Sapphire Tube |

||

Product Description

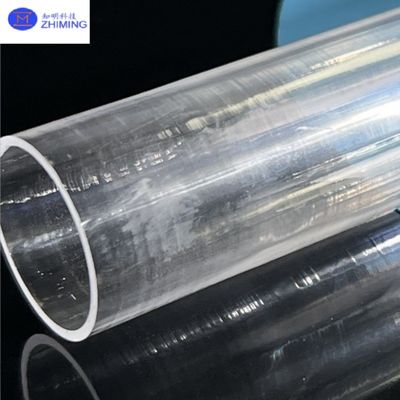

Product Introduction Of Sapphire Tubes

The Kyropoulos (KY) method sapphire tube is a single-crystal sapphire tube grown using the Kyropoulos technique. This method yields sapphire with excellent crystal integrity, controllable dimensions, and stable properties. KY-grown sapphire tubes are widely used in high-temperature, vacuum, corrosive, and optical environments. The method is ideal for producing large, high-purity sapphire crystals for commercial applications.

![]()

![]()

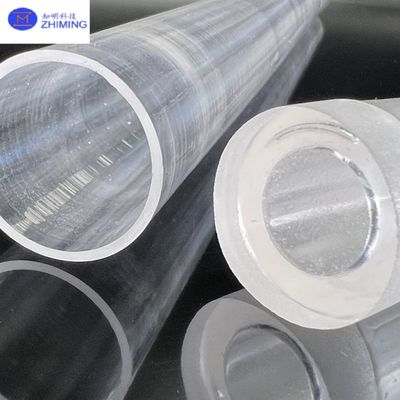

Working Principle Of Sapphire Tubes

The Kyropoulos method involves melting high-purity Al₂O₃ in a platinum crucible and slowly bringing a seed crystal into contact with the melt. Under carefully controlled temperature gradients and low pulling speeds, the crystal gradually grows while partially immersed in the melt. Unlike the Czochralski method, the KY method produces crystals with lower internal stress and fewer defects, enabling the growth of large, uniform sapphire boules suitable for tubing.

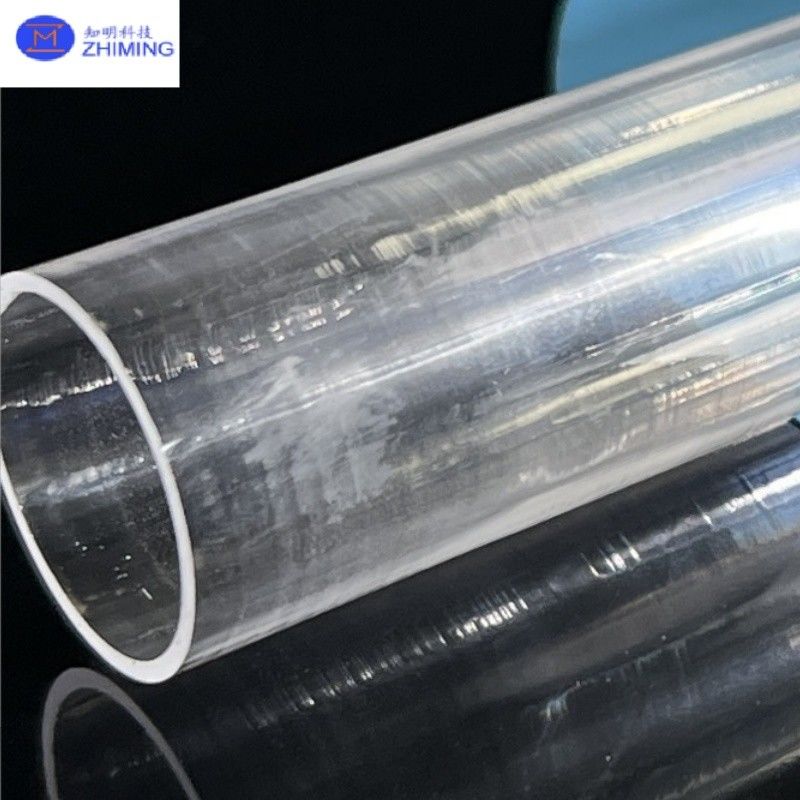

Applications Of Sapphire Tubes

Heating protection sleeves in high-temperature environments (furnace tubes, heating element covers)

![]()

Structural tubes in chemical or plasma-resistant environments

![]()

Enclosures for electronic or sensing components

![]()

Optical interfaces and protective sleeves in medical devices

![]()

Military & Aerospace: Windows and monitoring tubes for missiles or spacecraft.

![]()

Q&A Of Sapphire Tubes

Q1: What is the difference between KY sapphire tubes and EFG-grown tubes?

Q1: KY-grown sapphire offers superior uniformity, lower defect density, thicker walls, and larger diameters, making it suitable for high-performance applications. EFG is more suited for continuous production of smaller tubes.

Q2: What is the temperature resistance of sapphire tubes?

A2: Sapphire can withstand up to 2000°C in air and around 1900°C in vacuum or inert atmospheres. With a melting point of approximately 2050°C, it is ideal for high-temperature furnace tubes and thermal shielding applications.

Q3: Is it possible to customize sapphire tubes?

A3: Yes. Please provide specifications such as outer diameter, inner diameter, length, and tolerance—custom quotes will be provided accordingly.

Q4: Are sapphire tubes chemically resistant?

A4: Yes. Sapphire has excellent chemical stability and can withstand most acids (except hydrofluoric acid and hot phosphoric acid) and organic solvents, making it ideal for corrosive environments.

Related products

99.995% Al2O3 Transparent Sapphire Tube With High Tolerance Translucency

Sealed Sapphire Tube Aluminum Oxide Polished Single Crystal Corrosion-Resistant